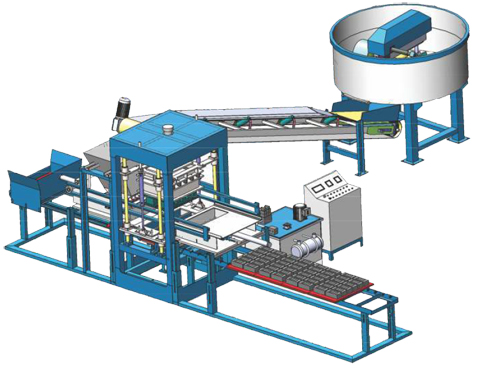

QT10-15 brick making machine

First, the producing process of QT10-15-type fire-free brick making machine,

The loader send the sand, gravel and other raw materials into the PL1200 ingredients machine hopper, measured by the electronic meter, according to the computer stored formula for ingredients (also random adjustment), after measured the material transport into the JS750 mixer hopper though the conveyor, and then by the hopper to sent the material to the mixer bunker. Cement and fly ash are also sent by the screw conveyor to the weight metering above the mixer and then directly into the mixing tank, then the water is also add into the mixing tank for mixing which is measured according to the design of water-cement ratio. After mixing for about 3 minutes, the 8 m belt conveyor will transport the mixed material to the QT10-15 brick making machine storage hopper. And then sent the charging material to the top of the mold by the molding machine, the material shaft rotation to produce centrifugal feed the material into the mold box forced, after the completion of charging material, the material machine back to the post, the pressure head at the same time the vibrator start working on the material vibration, after forming the mold box lift the product will be squeezed out, then send machine push the product to the above, after cleaning the surface by clean machine,the production will be send to the stacking machine, and then transported by the forklift for maintain in maintenance room.

The application of QT10-15 brick making machine is for the production of various wall tiles, pavement, road, slope, grass bricks, squares, lanes, pier, etc.

1, The products size : 1000 × 850 × 60-200mm;

2, The pallets size: 1100 × 900 × 30mm (wooden pallets);

3, The number of forming blocks: 390 × 190 × 190,10 block / die.

4, The forming cycle: 15-25s;

5, The productivity: 20m3 / h (standard block theory calculation);

6, The vibration frequency: 2800-4500 times / min (adjustable frequency);

7, The system work pressure: 21Mpa;

8, The exciting force: 660kN;

9, The host power 44.58kw;

10, The machine dimensions: 7150 × 2240 × 3000mm.

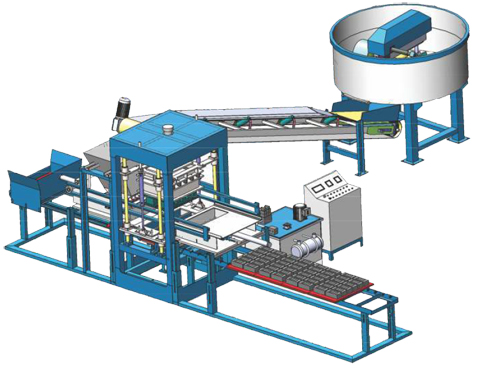

The loader send the sand, gravel and other raw materials into the PL1200 ingredients machine hopper, measured by the electronic meter, according to the computer stored formula for ingredients (also random adjustment), after measured the material transport into the JS750 mixer hopper though the conveyor, and then by the hopper to sent the material to the mixer bunker. Cement and fly ash are also sent by the screw conveyor to the weight metering above the mixer and then directly into the mixing tank, then the water is also add into the mixing tank for mixing which is measured according to the design of water-cement ratio. After mixing for about 3 minutes, the 8 m belt conveyor will transport the mixed material to the QT10-15 brick making machine storage hopper. And then sent the charging material to the top of the mold by the molding machine, the material shaft rotation to produce centrifugal feed the material into the mold box forced, after the completion of charging material, the material machine back to the post, the pressure head at the same time the vibrator start working on the material vibration, after forming the mold box lift the product will be squeezed out, then send machine push the product to the above, after cleaning the surface by clean machine,the production will be send to the stacking machine, and then transported by the forklift for maintain in maintenance room.

The application of QT10-15 brick making machine is for the production of various wall tiles, pavement, road, slope, grass bricks, squares, lanes, pier, etc.

1, The products size : 1000 × 850 × 60-200mm;

2, The pallets size: 1100 × 900 × 30mm (wooden pallets);

3, The number of forming blocks: 390 × 190 × 190,10 block / die.

4, The forming cycle: 15-25s;

5, The productivity: 20m3 / h (standard block theory calculation);

6, The vibration frequency: 2800-4500 times / min (adjustable frequency);

7, The system work pressure: 21Mpa;

8, The exciting force: 660kN;

9, The host power 44.58kw;

10, The machine dimensions: 7150 × 2240 × 3000mm.

Inquiry

| (Please write down the product model or any requirement) | |

| E-mail: | |

| Message: | |

Contact Information

E-mail:chris@concretebatchplant24.com

Tel: +86-371-65621392

Fax:+86-371-86616825

Add : No.14 Waihuan Road,New strict,Zhengzhou,China