Feeding belt conveyor repairs and maintenance

Feeding belt conveyor repairs and maintenance

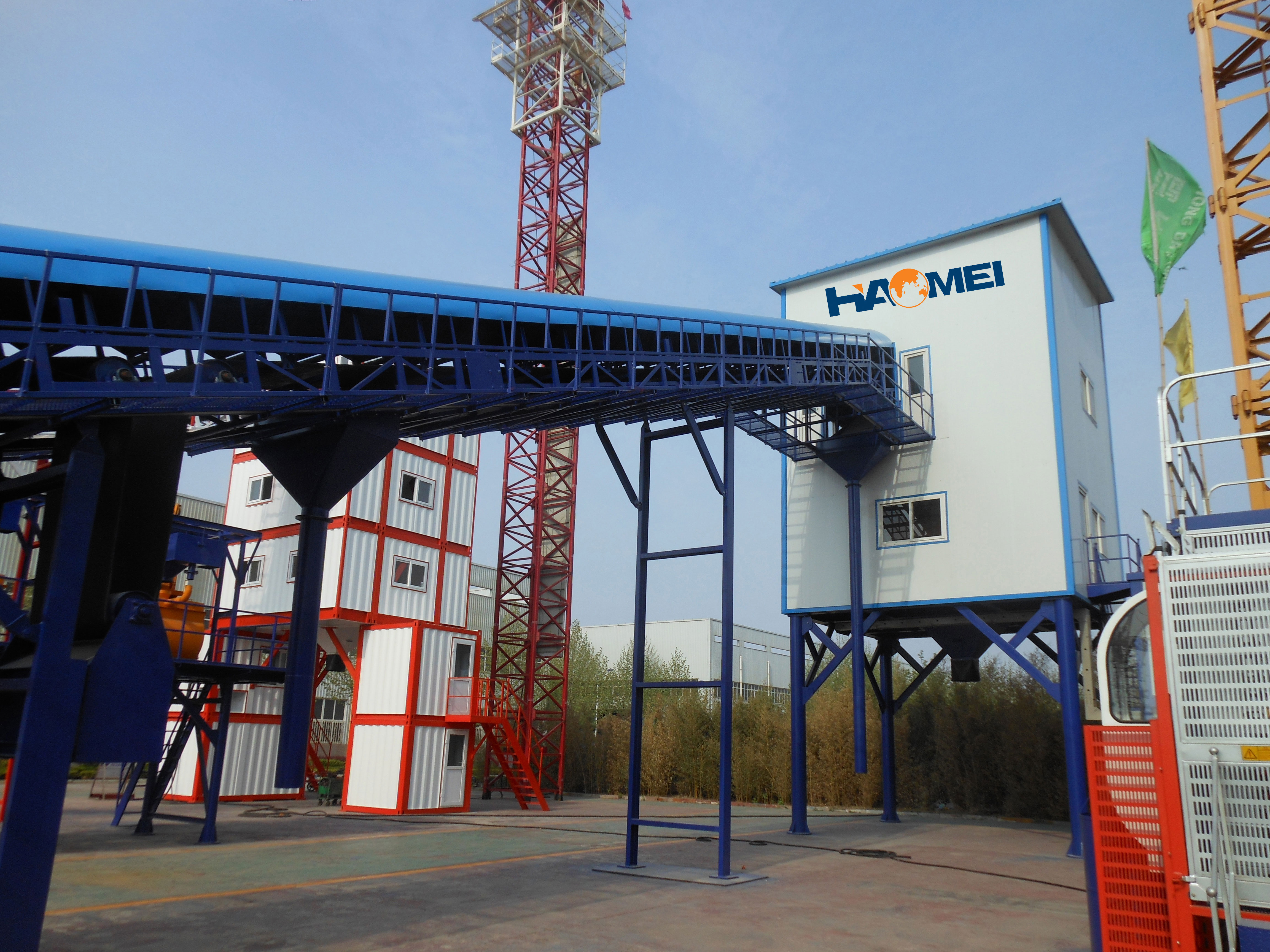

For ready mixed concrete batching plant belt conveyor, if we want to maintain and repair it perfectly. here haomei will share some tips with you and hope this can offer you some useful informations.

1. An internal gear motor consisting of the installation of 150 extreme pressure industrial gear oils, fuel injection must be strictly in accordance with the nameplate value. Too much or too little oil will affect the normal drum motor power and jobs. Replace electric drum roller in the job 200-300 hours in the future, the next oil change once every 500 hours, when an oil change with the progress of the two unscrew the oil plug and rotating drum, so that in the lowest position until the internal gear motor oil all done and stops.

2, the end of the tensioning roller bearing interior write ZG-5 grade calcium smooth resin and coated with smooth grease on the screw. Each station classes in the future should be finishing tape underside, idlers and rollers residue appearance.

NOTE: The tape machine is necessary to launch under no-load condition, otherwise there is the risk of damage hormones motor.

Inquiry

| (Please write down the product model or any requirement) | |

| E-mail: | |

| Message: | |

Contact Information

E-mail:chris@concretebatchplant24.com

Tel: +86-371-65621392

Fax:+86-371-86616825

Add : No.14 Waihuan Road,New strict,Zhengzhou,China