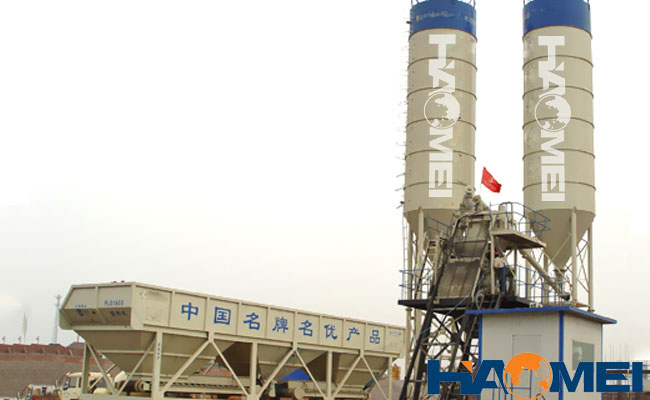

Improve the productivity of batching plant thailand

When using batching plant thailand in the production of commercial concrete operations, all aspects must be in a scientific budget, high efficiency is the key to multi-profit, using scientific methods to improve the efficiency is the guarantee for the continuous development of the batching plants, it not only win more profits, but also improve the competitiveness. So how do we improve the productivity without changing quality?

Charging time, mixing time and discharging time are the three time nodes that affect the production efficiency of the batching plant thailand.

First of all, the user should regularly check the butterfly valve and related electrical components to ensure that the mechanism runs smoothly and the connection between the powder hopper and the mixer is smooth, thus the normal charging time can be ensured.

Secondly, the user should check the integrity of the concrete mixer inside liner, the raw materials delivered location, the delivery time period, whether there is a phenomenon of holding the shaft affecting the mixing effect and time;

Then, the discharge time can be reduced by increasing the capacity of the discharge hopper or designing the discharge hopper as a storage container.

Finally, users should allocate enough concrete mixer trucks based on the production capacity and transportation distance of the batching plant for sale so that the commercial concrete can be timely transported.

Therefore, we must constantly maintain and manage the equipment at the batching plant so that the equipment is in the best working condition. In the daily maintenance, we can check the safety hazards in time and eliminate them to ensure that the batching plant is safe and efficient.

Charging time, mixing time and discharging time are the three time nodes that affect the production efficiency of the batching plant thailand.

First of all, the user should regularly check the butterfly valve and related electrical components to ensure that the mechanism runs smoothly and the connection between the powder hopper and the mixer is smooth, thus the normal charging time can be ensured.

Secondly, the user should check the integrity of the concrete mixer inside liner, the raw materials delivered location, the delivery time period, whether there is a phenomenon of holding the shaft affecting the mixing effect and time;

Then, the discharge time can be reduced by increasing the capacity of the discharge hopper or designing the discharge hopper as a storage container.

Finally, users should allocate enough concrete mixer trucks based on the production capacity and transportation distance of the batching plant for sale so that the commercial concrete can be timely transported.

Therefore, we must constantly maintain and manage the equipment at the batching plant so that the equipment is in the best working condition. In the daily maintenance, we can check the safety hazards in time and eliminate them to ensure that the batching plant is safe and efficient.

Inquiry

| (Please write down the product model or any requirement) | |

| E-mail: | |

| Message: | |

Contact Information

E-mail:chris@concretebatchplant24.com

Tel: +86-371-65621392

Fax:+86-371-86616825

Add : No.14 Waihuan Road,New strict,Zhengzhou,China