Drum Mobile Concrete Batching Plant

- Condition: New

- Delivery port: Qingdao or Tianjin port, China

- Payment term: L/C, T/T

- Guarantee period: 12 months

- Delivery time: 10-15 days after received deposit

- Installation time: 20days

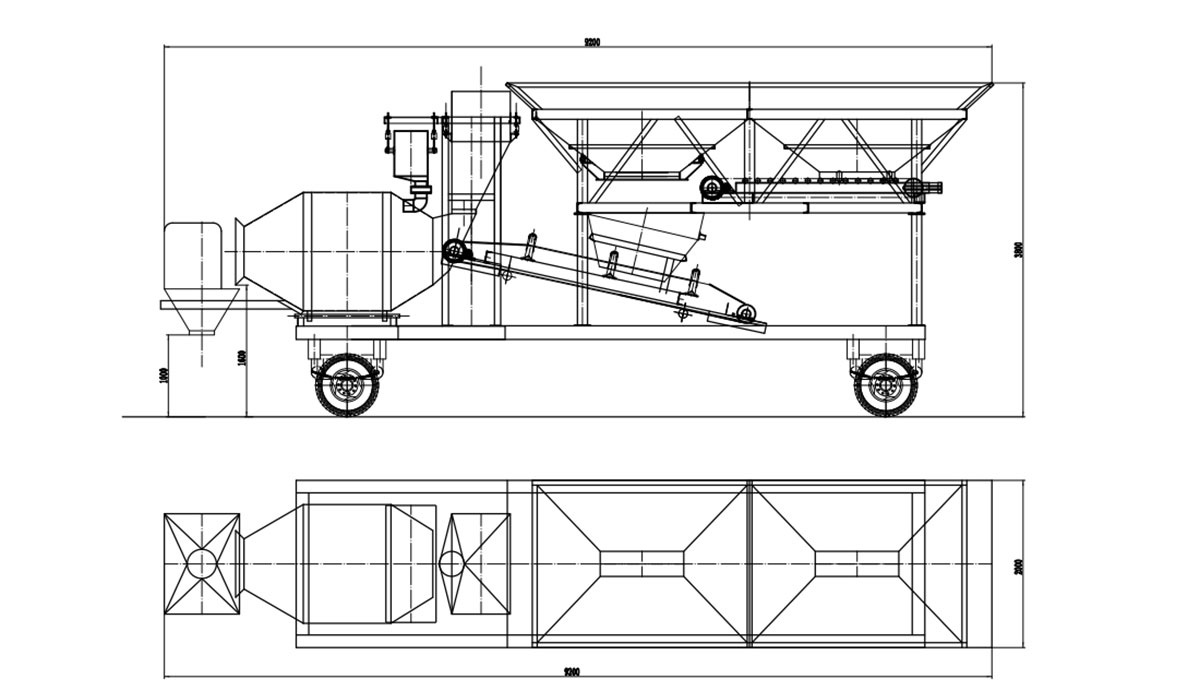

A drum mobile concrete batching plant is a movable concrete mixing plant equipment. Through clever design, the batching system, weighing system, mixing host, material storage, unloading and automatic control system of the concrete batching plant are equipped in a trailer unit, and the movement of the mixing station is realized through a trailer.

Structure of Drum Mobile Concrete Batching Plants:

1. Concrete mixer chassis: a cantilever-shaped mixing main engine chassis, which contains tow truck traction pins and parking legs; The weighing scale of mixer, cement and water admixture is placed on the chassis; inspection walking platform, railing, etc. are attached to the periphery.

2. Control room: The control room is located at the bottom of the main chassis, and is equipped with a fully automatic mixing plant control system that is the same with that of a stationary concrete batching plant. The control room is used as the front supporting point of the whole station when it is working, and the control room is stowed and stored in the bracket during site transfer, and all control lines do not need to be disassembled.

3. Aggregate batching measurement: this system is located at the back end of the whole station. The upper part is an aggregate (sand, stone) storage hopper. The storage hopper can be divided into 2 or 4 grids, and a heightening plate is set to increase the storage capacity. Pneumatically open the door in sequence, and the aggregate is measured in cumulative measurement of a variety of materials. The bottom is equipped with a walking rear axle and frame legs for working.

4. Belt conveyor frame: This frame is a truss structure connecting the mainframe chassis and the aggregate batching frame. It is equipped with a belt frame; the main frame, belt frame and batching frame are combined to form the main structure of the entire mobile mixing plant

5. Peripheral parts: the cement silo and screw conveyor. The peripheral parts are integral parts regardless of working or transportation states, so they can be transported and disassembled as a whole without disassembly.

Technical Parameters of Drum Mobile Concrete Batching Plant:

| Model | JZM500-2 | JZM750-2 | JZM1000-3 | JZM1500-2 | |

| Theory capacity | 25m³/h | 35m³/h | 50m³/h | 75m³/h | |

| Discharging height | 1600mm | 1600mm | 1600mm | 1600mm | |

| Total power | 44kw | 50kw | 58.9kw | 66.9kw | |

| Dimension(L * W * H) | 8 X 2.2m X3.8m | 8m X 2.2m X3.8m | 13.5m X 2.3m X 4.2m | 12m X 2.3m X 4.2m | |

|

Mixing System |

Model of Mixer | JZM500 | JZM750 | JZM1000 | JZM1500 |

| Mixing motor | 2*5.5kw | 2*7.5kw | 2*11kw | 2*15kw | |

| Discharging volume | 500L | 750L | 1000L | 1500L | |

|

Aggregate System |

Model of Batcher | PLD800-2 | PLD1200-2 | PLD1200-3 | PLD1600-2 |

| Aggregate bin volume | 5m³×2 | 6m³×2 | 7m³×3 | 8m³×2 | |

| Max. Aggregate Dia | 60/80mm | 60/80mm | 60/80mm | 60/80mm | |

|

Measurement System |

Cement weighing hopper | 500KG | 500KG | 560KG | 900KG |

| Water weighing support | 220KG | 220KG | 220KG | 330KG | |

| Additive weighing support | 30KG | 30KG | 30KG | 40KG | |

| Trailer Speed | 40-60Km/h | 40-60Km/h | 40-60Km/h | 40-60Km/h | |

| Optional cement silo | 50/100T | 50/100T | 50/100T | 50/100T | |

Features of Drum Type Concrete Batching Plant:

1. Rapid and easily to assemble and disassemble, conveniently to transport. All of the cable connection don’t need to be unloaded, except the external equipment such as screw conveyor and cement silo, etc.

2. The performance of mixing is perfect. It adopts drum type concrete mixer to make the concrete mixing equally in shortest time.

3. For different mixture radios of dry concrete, semi-dry concrete, or plastic concrete, it can make the mixing well.

4. Top-quality configuration, high reliability, accurate measurement, easy operation.

Application Fields of Mobile Concrete Batching Plant With Drum Mixer:

Drum mobile concrete batching plants are the best concrete mixing plant model for road, railway, bridge, port, hydropower and other projects.

1. Railway

High degree of automation and high production efficiency make production and processing easy and efficient.

2. Highway

High mixing quality and short cycle time. It is an essential mechanical equipment in road construction.

3. Bridge construction

The triple superiority makes it irreplaceable in bridge construction.

4. Water conservancy construction

Convenient operation and stable operation make water conservancy construction more convenient.

5. Port and dock facilities

A simple mobile concrete batching plant is formed to make port and wharf construction easier.

Haomei YHZM Series Mobile Concrete Batching Plant Cases:

we will suggest you the best suitable solution according to your requirement >>

Products Category

Inquiry

| (Please write down the product model or any requirement) | |

| E-mail: | |

| Message: | |

Contact Information

E-mail:chris@concretebatchplant24.com

Tel: +86-371-65621392

Fax:+86-371-86616825

Add : No.14 Waihuan Road,New strict,Zhengzhou,China