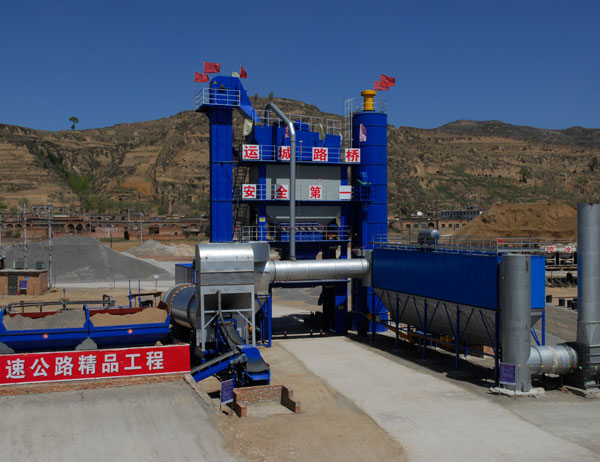

LB1000 Asphalt Mixing Plant

- Condition: New

- Delivery port: Qingdao or Tianjin port, China

- Payment term: L/C, T/T

- Guarantee period: 12 months

- Delivery time: 10-15 days after received deposit

- Installation time: 20days

LB1000 Asphalt Mixing Plant

Asphalt mixture Advanced computer control system

1.Separted strong current and weak current

2.A dual temperature cabinet air condition

3.The room is insulated by rock wool

4.Own R&D control system

5.Imported PLC & WEIGHTING instrument

Strong-current cabinet

1.Adopt the GGD cabinet conforming to the national standard

2.Source electric control units from Siemens

3.Orderly wiring, clear maekers and convient overhaul

Environmental dust ewmoval system

1.The bag filter from DuPont: NOMEX needle felt

2.Electric pulse structure

3.Emission concentration of dust less than 50mg/Nm3

Dual-motor driven agitator

1.Wear resistant blade

2.A synchromesh gear

3.Horizontal Double-shaft

High-efficiency vibration screen

1.Driven by dual motors

2.Convenient maintenance

3.Vibrating shaft installed outside the housing of the vibrating screen

4.Movable slide board

Newly-designed drying system

1.Specially designed blades

2.With an insulating layer

3.Direct-coupled gear reducer driving through crosshed universal joint.

Technical parameters

| Specification | Value |

|---|---|

| Type | LB1000 |

| Production Capacity(t/h) | 80 |

| Motor Power (kw) | 230 |

| The weighing Accuracy(%)Bitumen | +0.20 |

| The weighing Accuracy(%)Power | +0.25 |

| The weighing Accuracy(%)Aggregate | +0.5 |

| Way of dust filter | Bag dust filter |

| Dust emission | <=100 |

| Type of storage | side-type |

| Volume of storage (T) | 60 |

we will suggest you the best suitable solution according to your requirement >>

Products Category

Inquiry

| (Please write down the product model or any requirement) | |

| E-mail: | |

| Message: | |

Contact Information

E-mail:chris@concretebatchplant24.com

Tel: +86-371-65621392

Fax:+86-371-86616825

Add : No.14 Waihuan Road,New strict,Zhengzhou,China